Thoughts While Running #31

tariffs suck.

I spent two hours of my day yesterday on hold with UPS because I placed an $800 reorder with a brand (we already stock). It should have been under the de minimis threshold but instead arrived COD (cash on demand) for $503. Hilariously as I edit this at 5:30 am I’m currently back on hold (which based on call volume, my estimated wait time could exceed one hour) because by the time I actually got transferred to the correct department (which I’d already been transferred to once) they were closed.

The only answer I’ve gotten so far is via email, where I was told that the bill was for reciprocal tariffs as the goods were produced in South Korea (but shipped via the UK). The average email response time is appx. 4-10 business days because as I was told, they’re very, very busy.

According to the White House’s ‘fact sheet’ (ha) Trump’s tariffs are determined to ‘boost American manufacturing and protect jobs’ and to ‘strengthen the international economic position of the United States’. In the past seven months, everyone seems to have become an expert in tariffs. We’re being told that the countries being tariffed will absorb the costs (they’re not) and these fees won’t be passed along to consumers (they are). They’ve been ruled illegal twice but no one is clear if the ruling will stick, if they’ll actually be refunded and how the Supreme Court might rule if + when it comes time.

Cheap labor might be the original reason most manufacturing left the US (the ‘china stole our jobs’ spiel). The number of garment workers in the US decreased from 2.4 million in 1970 to 100,000 today as companies went in search of cheaper labor elsewhere. Corporate greed might have been the initial reason for the shift, but the American consumer has helped keep it there. We’ve grown so accustomed to disturbingly low price points (especially in fashion) that it would be impossible to move manufacturing back to the US and still maintain current product costs. We stock a brand of bags in store that are beautifully made, lightweight and manufactured domestically - the biggest feedback? The price point. Why pay $295 for a packable backpack when you can buy it for a fraction of the cost elsewhere?

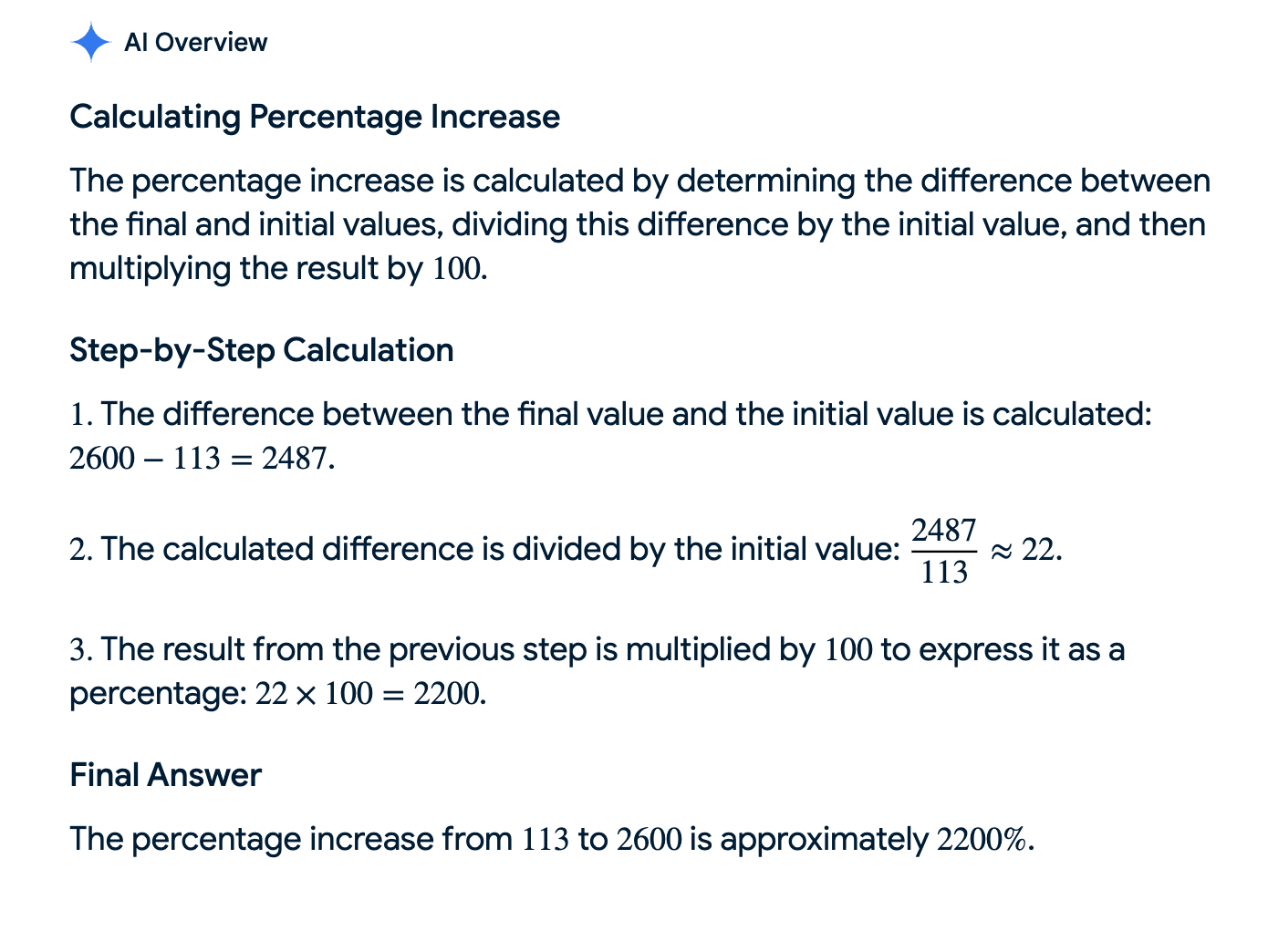

The average monthly salary of a garment worker in Bangladesh is $113 with the average cost of living per person around $240-$300. If that same garment worker were in the US making minimum wage ($16.90/hr by California standards although there are reports of worker making much, much less), they’d be making appx $2600 before taxes. Most apparel factories are in major cities like LA + NYC, where the cost of living on average is appx $3500 according to google.

I find it hard to believe that the American consumer, the one who was so concerned about the cost of eggs they elected a convicted felon as president, would be willing to pay at least 2x for a piece of apparel. So while Americans might not be responsible for the shift to oversees manufacturing, we are responsible for keeping it there.

Is it like this for other industries? I don’t know because I’ve spent my entire career in the apparel industry but I’d assume as much. If you’ve ever driven through the less affluent suburbs of Detroit and seen the skeletons that remain of the auto manufacturing factories I would imagine it’s not that far off. It would take years, decades even to fully restore these factories and even then, would they actually be able to handle the volume of demand? Potentially not.

There’s also another reason all your running shoes are made in Vietnam and all your running apparel is made in Portugal that no one seems to be talking about. It’s because these countries are better at it.

I designed accessories across four different retail brands and at each company, our factories were all located in the same region of China (some even shared the same factory). At Lululemon we manufactured our more technical packs in Vietnam alongside The North Face, Burton and Eastpack. This factory was set up with the necessary machinery to do the technical constructions required to manufacture the bags we wanted to make. Ultra sonic welding (which involves construction without sewing), molding capabilities, onsite testing (did you know your running pack was tested to hold 50 lbs?). The sheer cost of setting this up in another country, excluding the cost of labor, would prove prohibitive for even the largest of brands.

I no longer am on the design side of the industry so I can’t pretend I know the most relevant information, and large brands have entire sourcing + production teams set up to navigate tariffs + the associated headaches that come alongside importing goods. An old colleague DM’d me yesterday that she too had been on the phone with UPS all day because they weren’t receiving their production packages. I don’t know if I feel better or worse knowing that a billion dollar company is experiencing the same issues that I am.

A year ago when the world still felt normal and the store was about to open, Kamala Harris had promised a $50k tax break for new businesses as one of her campaign promises. I remember wondering if I’d still be eligible since I was opening in 2024. Joke’s on me because there are no breaks in business under Trump’s America unless your business is in the billions and your last name is Zuckerberg or Bezos or Cook.

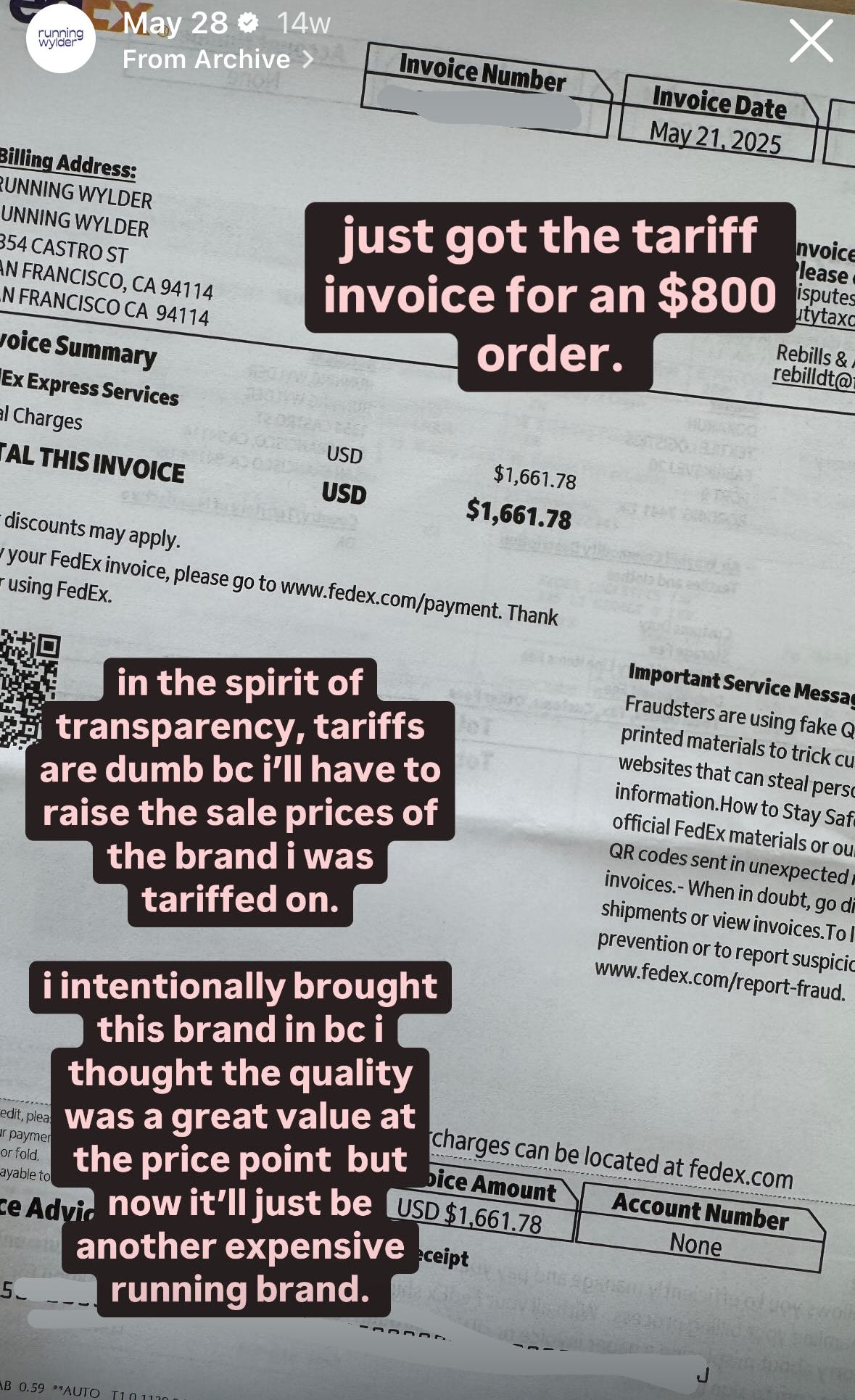

Last year at this time I was placing all my opening orders and didn’t even think to inquire about any additional fees or tariffs. Most brands simply absorbed the costs or baked them into their wholesale price already, the one exception being Circle, a small brand based out of Paris. We were their first US customer so we were navigating the import seas together; ones that at the time seemed complicated but looking back were hilariously simple by contrast.

I’ve paid thousands of dollars in tariffs over the last few months. On an $886 order from Denmark, I paid $1661 because unfortunately the EU hadn’t renegotiated the tariffs yet. Luckily the retail price is 3x wholesale (as opposed to the standard 2x) so I’ll be able to break even; assuming of course everything sells. A more recent order of $1065 from another Danish brand came with a $221.87 bill due upon delivery. Another from a Swedish brand ~ $3000 euro, $1049 in tariffs. For most goods, my margins range from 40% - 50%, which might sound like a lot but it isn’t - most of what i make goes right back into the store to cover operating costs, employee wages, store events + inventory expenses amongst many other things. Tariffs erode appx. half of this margin, reducing it to 25% or in some cases 0, making it nearly impossible to justify carrying some of these brands as I won’t raise my prices beyond what their listed retail price is online.

In the early days of the tariffs I’d receive a bill in the mail a week or two post delivery. Now when the goods arrive they won’t leave the package unless I give them cash or a check (they aren’t set up for credit card payment, apparently) which is how I ended up on the phone for 2 hours yesterday.

I haven’t read many or really any articles specifically highlighting the impact of tariffs on small businesses. Billion dollar brands will be fine. I don’t care about how the Gap plans to navigate the tariffs because they will be ok. Perhaps they have to exit a category because it’s too expensive to make (while I was at Old Navy during Trump’s first administration, they stopped making handbags because the tariffs ate away so much margin it wasn’t worth producing). Shareholders might get pissed when earnings are a little lower for the quarter, but they’ll weather the storm until they figure out a work around.

Small businesses aren’t built to weather storms. We’re small, cash strapped operations that are often self-funded. Stores aren’t in control of where products are manufactured and we’re at the mercy of what the brands we carry decide to do. Small apparel brands struggle enough to find factories that will manufacture their goods for a variety of challenges : cost and minimums being the two biggest. Cost goes up, they can’t afford to buy more and it gets tougher to meet minimums.

The Old Navy’s, the Gaps, the Nikes of the world are all able to negotiate with factories and suppliers based on volume. Perhaps they can even convince the factories to absorb some portion of the fees but it’s highly unlikely they’ll absorb it all as profits margins are already squeezed; fabrics purchased years in advance, designs cost engineered to their fullest potential.

Many of the brands (at least half) I stock are so small they don’t have this luxury and I struggle to understand why purchasing from a small brand - US based or not - should be punished.

The reality of globalization is that we’re all connected, regardless of which country you call home. We no longer have to board an airplane to shop stores from Paris - we can merely hop online and purchase whatever we what from whomever we want. As long as we can also afford all the additional bills that come with it.

With globalization comes diversity and I don’t thing that’s a bad thing. Tariffs however will make it harder to access goods, broadening the divide between those who can afford and those who cannot. Unfortunately, goods produced overseas are the ones that are the most accessible for most Americans to buy which are also the ones being tariffed the highest.

The TL:DR to all of this (if you’re still with me) is that the tariffs suck. Literally no one will benefit, except the US government which brought in an estimated $94 BILLION dollars since tariffs went into effect in April. They’ll make it harder for small businesses to survive and it’ll raise the cost of goods. Manufacturing most likely will not return to the US and we’ll just end up paying more for the same stuff we’ve always had.

*k

I’m sorry & sad that this is happening. As someone in healthcare, it’s horrifying to see the effects of this administration on the people who are the most vulnerable. Thanks for explaining and breaking it down why the tariffs are hurting small businesses for someone who doesn’t know that space!

So appreciate this take. As a new, small brand. The tariffs are not only crushing, the constant changes in policies makes is impossible to plan and make educated decisions